Or How I Remembered Why I Hate the Router.

The tailed router, obviously. The hand router I like. If you were to see how many I have of the darn things (and in truth, I'm not absolutely sure myself) you might say I have a router problem. This is not so; they've just kind of accumulated. At some point there's going to be the mother of all tool sale lists, honest.

No, it is the Tailed Demon that I hate, loathe and do my level best to avoid. I think all my really serious woodworking disasters can be traced to the router. The

plunge lock has failed, the

collet's failed mid-cut, the whole thing has just ceased to work after very little use, that sort of thing. The electric router and I are Not As One. It's largely responsible for my embracing of the humble hand tool - essentially it boils down to the fact that I can't muck things up quite so fast with hand tools.

But a friend made a request. Yes, I can hear the seasoned woodworker saying "Uh-oh" already. But no, there was no pressure, and if I was to back out entirely I was given to understand our friendship would not automatically be at an end. But ya know how it is; you want to please, don't ya? So I offered a tentative "Um, o-kay...". The task? Little wooden plinths for model horses.

I'll be honest, I'm not a fan of real horses, and the idea of having models of the daft creatures about the place leaves me as puzzled as my elder brother's desire to spend his limited spare time trying to wire up his model train layout. But there we are, model horses it is. You customise them and stuff, I gather. There are shows. Anyway, my second mistake. I'd failed to appreciate the sizes we were talking about. These things are small, ergo the little wooden base upon which they decoratively stand are thus also small. The longest dimension was no larger than 110mm (approx. 4 3/8") in this case. So essentially we're talking very small bits of wood with a profile round the sides.

Obviously one for the scrap box then. If you've been following this blog for a while, you may have noticed my "project stock" would sometimes struggle to make it into some folks' off-cuts bin, so you can imagine what my scrap box is like. But the gods gave this sucker a break and offered up some suitable stuff for the required three bases, plus some spares. Just as well about the spares really. So I planed it up, cut to size, all ready for the fancy bit.

Obviously this is the kind of thing the router lives for, right? In other hands, yes. In mine? Well, it went like this. First I went to the Drawers o' Cutters, hacked my way through the cobwebs, and refreshed my memory of what profile cutters I own. It turned out there were two. They came in a set I bought, ooo, waaaaaay back when I first started my running feud with the router. The set was by Freud, which could have been taken as prophetic - the use of them leading me to the brink of needing some sort of psychoanalytic help. Anyway... One was an over-exciteable Ogee which was too large for the 10mm thick stock. The other an Ovolo. Or rather it would be if I could get the bearing off in order to make it one instead of a fairly tame roundover.

I've never removed any of the bearings from any of the cutters in that set in all the years I've had them. I know what you're thinking; I was thinking it too. I laid my hands upon the appropriate hex wrench and... it came undone just like that. I didn't know it then, but the gods were merely lulling me into a false sense of security. So no bearing, and given the size of the workpiece anyway, this was a job for the router table.

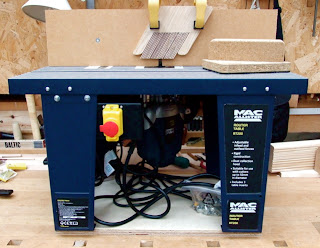

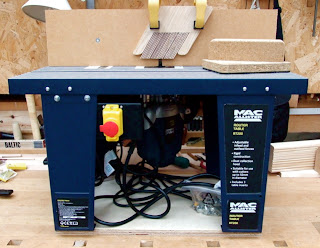

If the reader has a long memory, he or she may recall I couldn't resist a "bargain" and bought a Piece o' Tat ( ™) router table during a

fit of insanity.

I'd love to say it's proved itself a useful w'shop stalwart, but in truth I've not had call to use it. In the back of my mind I had a thought to leave it permanently set up to do stopped grooves for box bottoms - a task I do not relish with hand tools - but first you need to make something approaching a box side to groove. Anyway, now it could shine, and so I cheerfully fitted the cutter in the collet, finger-tightened it and looked round for the collet spanner.

Which has gone AWOL.

Okay, not a problem. I have a wide range of spanners for all eventualities always handily hung on the wall. I selected a couple of probables, found the 24mm did the job, and finished tightening up. Then I went to adjust the height. With 10mm thickness to play with, this is an exact science. Half a mm here or there made it look All Wrong. This router is not designed for exactness. Which, as it turned out, was lucky, 'cos that matched the router table it's fitted to. Eventually I got there, lined up the fence, clamped the table to the bench, got out the

My Little Dalek 'shop vac' and went to apply hose of same to dust extraction point in fence. Which didn't fit. Where is my all-rounder, rubbery, fits damn near anything, hose reducer doodah?! Gone! Vanished!

Reader, this was a numbing blow. I've had that widget since the early days and it's saved my bacon on numerous occasions. But extensive search has failed to find it. I admit I may have directed suspicious and pointed glances at the Old Man, but he claims innocence. What's worse is a replacement apparently demands spending over

Eight Earth Pounds. Egads. And you just know it'll turn up as soon as the new one's on its way...

However, I recovered from this shock, dragged myself from my knees (whence I had fallen, a cry of "Noooo" torn from my devastated person), slapped myself about the cheeks and advised myself to get a grip. Which I did, with the aid of a clamp and directing the hose in a general router direction below the table. Cutter set - check. Extraction set - check. Power on - check. Fire up the Piece o' Tat ™.

For the love of Norm, now I remembered the other reason I hate routers. Just running the thing makes it sound in horrible pain. Actually risk adding wood to the scenario and the thing sounds like it's being tortured with red hot pokers. Reader, I applied wood to router, but in truth my heart wasn't in it and it knew it. It chewed, it spat, it managed to defy all logic and create a result that shouldn't have been physically possible. Feeding finicky little pieces that demand pinpoint accuracy to get a reasonable looking result into the jaws of that router table with, as it turned out, sufficient enough flex in its top to make the result look like hell is not for me. It wasn't for the wood. The router wasn't keen on it either. We decided a mutual separation was the best answer. The router gets the cutters and I can take them to the zoo one weekend a month - if I want to - and I get the w'shop.

Now about now you're saying "But Alf, you could easily make this jig" or some other sound advice. And you're right, I probably could. But while I will apparently spend hours on the end result, I absolutely loathe spending a moment on making jigs. Especially when I won't use the thing again - and chances are it won't work for me anyway because it involves a router. Besides, I had another Thought.

I own a WoodRat. You have to be wondering why, given the preceding anti-router sentiment, but I do, and I'm reluctant to sell it because it is useful. It's probably been responsible for nearly all the successful routing I've ever managed.

The WoodRat could hold those finicky little pieces easy-peasy. A nice controlled cut, easily set up? What could go wrong. Well there's just one problem with the WoodRat; by the nature of the rodent you lose a certain amount of depth of cut. Naturally I'd forgotten that. I put the bearing-less profile cutter in the DeWally, plunged merrily away and...

See that fragment of red in the middle of the picture? That's the cutter at full plunge depth. Yup, about as much use to me as a chocolate fireguard.

By this point I'd spent an hour getting absolutely nowhere, I was extremely fed up, depressed at all the reminders of how things had got up and walked away waiting for me to actually ever being in the w'shop again, and to top it off had managed to nick my fingers on the cutter not once but three times simply because it was so cold I couldn't actually feel my fingers. I was about ready to declare I would henceforth go through life utterly friendless and be better for it. You don't want to know what I'd have done to any model horse unwise enough to gallop across my path at that moment.

So I went and considered some suitable phrases to break the news to my friend. My sorrow and regret would drip from every word, but alas, the w'shop had burnt to the ground and I couldn't do it... No, no, Alf! Is this the attitude that founded empires? It is not. Empire builders tended to steer clear of routers and favour the honest toil of subjugated natives. I wondered if I could find a Cornishman to do it.

No, I didn't really. As ever, I turned to hand tool methods to see if they would save those little horses from going plinth-less. But I'll tell you about that tomorrow...